IC*STAR: New Ways in Woven Sack Production

A stronger sack bottom, material savings, low maintenance requirement – woven polypropylene sacks welded with a sealing band instead of sewn at the bottom bring significant advantages for both producers and users and help protect the environment.

With the IC*STAR sack concept, developed and realised by Starlinger and STATEC BINDER, broken needles, stitch holes and traces of oil on the sack fabric are now destined to become obsolete. ‟Closure of sacks by welding is the solution of the future for standard woven sacks,” Hermann Adrigan, Sales Director of Starlinger & Co. GmbH is convinced. ‟Compared to sewing, the IC*STAR process offers considerable material savings in sack production, consequently requiring less raw material – polypropylene, in this case. Sack producers profit from lower costs, and the reduced carbon footprint is good for the environment.” Material is saved by the elimination of the seam allowance required for a sewn closure, as well as by the use of lighter fabric made possible by the greater sack bottom strength. Moreover, this type of closure makes IC*STAR sacks completely tight – an important advantage especially for packaging fine powdered goods which tend to sift through stitch holes and form dust, presenting a health hazard in some cases. The oil-free production process makes IC*STAR sacks ideal for packaging foodstuffs.

Welded sacks – the production concept of the future

IC*STAR sacks are produced on the Starlinger sack conversion line multiKON KX. This conversion line is equipped with the sealTEC bottom closure module, jointly developed by Starlinger and STATEC BINDER. Instead of a sewing unit, the IC*STAR concept features a welding device which, in a continuous process, welds a coated sealing band onto the sack bottom by means of hot air – no glue is required. The mouth of the sack remains open and can be closed, after filling on the filling line, either by welding with another sealing band or by sewing. The sealTEC module requires less maintenance than a sewing machine and needs considerably fewer replacements of spares and wearing parts. Both coated and uncoated IC*STAR sacks can be produced by this new method in an efficient and material-saving process.

_______________________________________________________________________

About STATEC BINDER:

A specialist in packaging and palletizing machines, STATEC BINDER GmbH is a globally operating manufacturer of flexible solutions for the bagging and palletizing of bulk goods. The product portfolio ranges from bagging systems for polyethylene, poplypropylene and paper sacks to high-level palletizing systems and robot palletizers, renowned for reliability and durability.

STATEC BINDER develops, designs and manufactures all machines in its own ISO 9001 certified plant in Gleisdorf, Austria. To date, approximately 1000 packaging lines have been supplied and installed worldwide.

About Starlinger & Co. Ges.m.b.H.:

Starlinger is a Vienna-based engineering company with production sites in Weissenbach and St. Martin, Austria, as well as Taicang, China. As the world’s leading supplier of machinery and complete lines for woven plastic bag production and PET recycling and refinement, Starlinger & Co. Ges.m.b.H. is a synonym for leadership in quality and technology in over 130 countries. Founded in 1835, the family-owned business has been exporting machines worldwide for more than 45 years with an export quota of over

99.5 %.

Branches in Brazil, China, India, Indonesia, Russia, South Africa, USA and Uzbekistan ensure quick and professional technical support and service.

Further information:

Starlinger & Co. Ges.m.b.H. Sonnenuhrgasse 4

1060 Vienna, Austria

T: +43 1 59955-0

F: +43 1 59955-25

E: sales@starlinger.com www.starlinger.com

Starlinger is a Vienna-based engineering company with production sites in Weissenbach and St. Martin, Austria, as well as Taicang, China. As the world’s leading supplier of machinery and complete lines for woven plastic bag production and PET recycling and refinement, Starlinger & Co. Ges.m.b.H. is a synonym for leadership in quality and technology in over 130 countries. Founded in 1835, the family-owned business has been exporting machines worldwide for more than 45 years with an export quota of over

99.5 %.

Branches in Brazil, China, India, Indonesia, Russia, South Africa, USA and Uzbekistan ensure quick and professional technical support and service.

Further information:

Starlinger & Co. Ges.m.b.H. Sonnenuhrgasse 4

1060 Vienna, Austria

T: +43 1 59955-0

F: +43 1 59955-25

E: sales@starlinger.com www.starlinger.com

battenfeld-cincinnati: Plast 2012 - Milan

Optimized

for pipe and profile

production

At this year’s Plast from 8 to 12 May, battenfeld-cincinnati will be

presenting optimized machine concepts for makers of pipes and profiles. At its

booth A 01 in hall 13, the German-Austrian machine manufacturer will showcase a

twin-screw extruder from its latest-generation twinEX series for profile

production and the solEX single-screw extruder for pipe extrusion. Information

will also be provided about greenpipe, the innovative energy-saving concept for

pipe production, and about techBEX, the complete line for producing small

technical profiles

A twinEX

78 parallel twin-screw extruder will be on display, the smallest model of the series,

which comprises a total of four models with screw diameters ranging from 78 to

135 mm. With its 34 D processing length and typical battenfeld-cincinnati features

– such as customized screw geometries, maintenance-free screw temperature

control and effective barrel cooling – these extruders reach outputs between

120 and 1,000 kg/h in PVC profile production. Of course, twinEX extruders can

also be used to produce pipes with output performances ranging from 200 to 1,700

kg/h. The machines stand out by their high flexibility with gentle, homogeneous

melt processing, and also offer a favorable price/performance ratio.

Moreover,

a solEX 75-40 from the company’s powerful single-screw extruder series will be

presented. The five models from the solEX series feature top performance in terms

of throughput and melt homogeneity in the production of HD-PE and PP pipes. They

reach an extremely high throughput level, which allows manufacturers to use the

next-but-one smaller machine model compared to conventional 30 D extruders.

Depending on the application and the material, outputs between 240 and 2,200

kg/h can be reached with screw diameters ranging from 45 to 120 mm. This high

performance is achieved by an optimized screw geometry and high torque in

addition to a screw length of 40 D. Like all extruders from

battenfeld-cincinnati, these extruder models also come with maintenance-free,

energy-efficient AC motors and an extremely compact design, so that their space

requirements are modest.

Another topic of this trade fair

is the modular greenpipe concept, which enables a drastic reduction in the

lengths and energy costs of pipe extrusion lines compared to conventional

lines, with simultaneous optimization of pipe quality. Processors have three

different options at their disposal: pipe dies with an efficient air cooling

(EAC) system, the KryoS pipe die series based on spiral mandrel distributors,

which allows reductions in energy consumption by 30 to 45%, and the greenpipe

downstream concept. The latter enables the length of the cooling section to be

cut almost by half. In the greenpipe downstream aggregate, fresh cooling water

is pumped only into the hindmost tank instead of every tank, then passed on

from one tank to the next from back to front in the opposite direction to the

extrusion process.

Finally, battenfeld-cincinnati will present detailed information in Milan about

the techBEX turnkey line concept for small technical profiles, which was

already presented in Italy during an Open House event at Fainplast s.r.l. in

Ascoli Piceno. Under the motto of “quality meets cost-efficiency”, techBEX

stands for a range of standardized, complete extrusion lines, which are able to

cover a wide range of applications. The total package consists of an extruder,

which can be selected individually from a choice of six different models, and a

completely wired and pre-assembled downstream section including everything from

the calibration table to the tilting table, which is ready for immediate

start-up on site.

Main events of the 6th World Water Forum in Marseille

battenfeld-cincinnati: Plast 2012 - Milan

Optimized

for pipe and profile

production

production

A twinEX

78 parallel twin-screw extruder will be on display, the smallest model of the series,

which comprises a total of four models with screw diameters ranging from 78 to

135 mm. With its 34 D processing length and typical battenfeld-cincinnati features

– such as customized screw geometries, maintenance-free screw temperature

control and effective barrel cooling – these extruders reach outputs between

120 and 1,000 kg/h in PVC profile production. Of course, twinEX extruders can

also be used to produce pipes with output performances ranging from 200 to 1,700

kg/h. The machines stand out by their high flexibility with gentle, homogeneous

melt processing, and also offer a favorable price/performance ratio.

Moreover,

a solEX 75-40 from the company’s powerful single-screw extruder series will be

presented. The five models from the solEX series feature top performance in terms

of throughput and melt homogeneity in the production of HD-PE and PP pipes. They

reach an extremely high throughput level, which allows manufacturers to use the

next-but-one smaller machine model compared to conventional 30 D extruders.

Depending on the application and the material, outputs between 240 and 2,200

kg/h can be reached with screw diameters ranging from 45 to 120 mm. This high

performance is achieved by an optimized screw geometry and high torque in

addition to a screw length of 40 D. Like all extruders from

battenfeld-cincinnati, these extruder models also come with maintenance-free,

energy-efficient AC motors and an extremely compact design, so that their space

requirements are modest.

Another topic of this trade fair

is the modular greenpipe concept, which enables a drastic reduction in the

lengths and energy costs of pipe extrusion lines compared to conventional

lines, with simultaneous optimization of pipe quality. Processors have three

different options at their disposal: pipe dies with an efficient air cooling

(EAC) system, the KryoS pipe die series based on spiral mandrel distributors,

which allows reductions in energy consumption by 30 to 45%, and the greenpipe

downstream concept. The latter enables the length of the cooling section to be

cut almost by half. In the greenpipe downstream aggregate, fresh cooling water

is pumped only into the hindmost tank instead of every tank, then passed on

from one tank to the next from back to front in the opposite direction to the

extrusion process.

Main events of the 6th World Water Forum in Marseille

Εcotec 2012 - Conergy

Clariant gives designers and brand managers vital insight with new color palettes

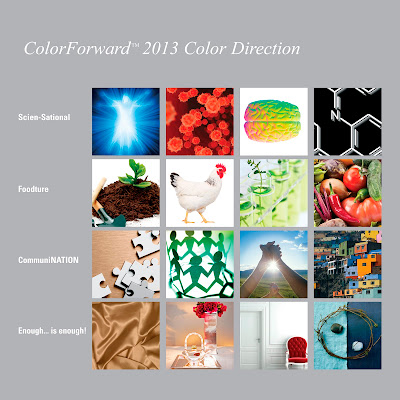

Color is a powerful communications tool with the ability to convey emotions and stories. It has deep connections with cultural, political, religious and social influences, as we all respond to color psychologically and intuitively. In a world filled with conflicts and pressures, the impact of color, whether conscious or subliminal, can bring value to our lives by positively influencing our moods. It can take us from sad to happy, tired to alert, anxious to calm. In knowledgeable hands, valuable guidance can be provided for applying color to real-world challenges to achieve desired outcomes. In the world of plastics, that guidance comes from Clariant's ColorWorks™ and its ColorForward™ color design tool.

ColorForward is a dedicated color forecasting service in the plastics industry, now in its 7th year. The newly launched ColorForward 2013 is a welcome event for designers and marketers of plastics products. Industry-wide, ColorForward’s predictions help define what colors consumers will respond to in the years ahead. The service has proven to be of great value to manufacturers of all types of products, giving them a head start on using the power of color to influence consumer purchasing decisions.

ColorForward’s color predictions are based on intensive research of the most influential societal trends around the world. Uncovering the most significant trends and the colors they engender is not a simple task. Each ColorForward forecast package is based on a year-long effort that involves hundreds of plastics industry and trend analysis experts from around the world. Color specialists from industries as diverse as architecture, textiles, packaging, housewares, automotive and fashion all participate in the process. Many trends are considered, but only the ones with true global impact make the final cut.

The color selections for 2013 are based on four powerful societal trends that are deemed to have the strongest global impact in the near time frame.

Let's tackle the problems of the world - Science Superhero

Climate change, diminishing energy supplies, feeding a growing global population, pollution of land and oceans, new disease threats are monumental challenges we wake up to daily. But, there is hope in a trend Clariant calls SCIEN-SATIONAL. It represents the growing sense of optimism we have in the capabilities of science and technology to find the best solutions. We fully support our scientists and believe their experimentation and explorations will yield amazing breakthroughs and achievements that will improve the quality of life for everyone on earth.

Feed me, and make it good – I’m Loving Eat!

Our food supplies have entered center stage. Food has taken on a greater meaning than mere sustenance in our lives. It's a trend Clariant callsFOODTURE. We live in a global society where what we eat, how it's grown, and where it comes from are important issues. TV channels dedicated to food, celebrity chefs, cookbooks by the score, and culinary tourism are examples of our obsession with what we eat and the search for new tastes. Urban vegetable gardens are commonplace. And new technologies are developing ways to produce food closer to where people live.

There's a group I'd like to join – Meet You There

People are feeling a need to join together with others who share the same interests and values. This is a drive to create communities of kindred souls that Clariant has named COMMUNINATION. These social networks, aided by rapidly growing communication technologies, will be both local and global. They will provide real benefits to members by enabling people to call on each other for assistance, for a cause, or simply for companionship. Another aspect of this trend is the interest in things produced and sold locally with special appeal for the "home-grown" and "hand-crafted" of true quality.

Do we really need more stuff? – Classy Austerity

It seems people have finally learned that accumulating possessions is not the route to happiness. Today's new generation feels they can enjoy life more by having less. This global shift from collecting stuff to choosing what we feel is essential, is a trend Clariant titled ENOUGH... IS ENOUGH! The downturn in the world economy, the "green" revolution, the desire for a less pressured lifestyle – all contribute to the new attitude against conspicuous consumption. We are willing to pay more for better quality, and we want our things to provide a meaningful experience.

Through their dedication, depth of experience, and true collaboration, not to mention a healthy dose of intuition, the worldwide Clariant ColorWorks team has developed a range of color palettes that harmoniously resonate with each trend’s influence. The color palette for SCIEN-SATIONAL represents a sense of the mystique and the joy of scientific discovery. FOODTURE's palette is very organic and brings to mind a bright, fresh, healthy and tasty salad. COMMUNINATION offers a warm palette that's clean, direct and grounded, supportive of our communal outreach. The colors of ENOUGH... IS ENOUGH! foster a sense of quality and durability along with our desire for an emotional connection.

The color palettes of these trends are quite varied and will give designers much to think about. "But that's the idea," says Cristina Carrara, Designer at ColorWorks Europe and a member of the Clariant Masterbatches global ColorForward team. "The colors are conceptual ideas. They are meant to inspire the imagination." Carrara also points out that the colors can be mixed and matched, and freely adapted to the needs of local markets or blended with regional influences.

"Our customers are eager to work with the next release of ColorForward every year,” says Maurizio Torchio, Head of ColorWorks Europe. “Finding it an inspiring and serious design tool. It is a challenging, creative puzzle they really have fun with."

Anyone interested in learning more about ColorForward can visit www.colorworks.clariant.com and click on the Color Trends tab. Clariant also offers seminars at the seven ColorWorks locations as well as at selected conferences and at customer sites.

Clariant Masterbatches products are marketed under the following global brand names: REMAFIN® olefinic masterbatches and compounds; RENOL® masterbatches and compounds based on engineering resins, styrenics and PVC; MEVOPUR® masterbatches for medical and pharma applications; CESA® additive masterbatches; HYDROCEROL® chemical foaming and nucleating agents; OMNICOLOR® universal color masterbatches, and ENIGMA® special effects. These brand names are all registered trademarks, and ColorWorks™ and ColorForward™ are trademarks of Clariant.

www.gpmagazine.gr

WM Wrapping Machinery sa

WM

Wrapping Machinery SA in Stabio, Swiss company established in the construction

of thermoforming systems, will take part in the PLAST 2012 trade fair in Milan

next May.

Especially

for this occasion, the new version of the Model FC 780 E Speedmaster Plus reel

thermoforming machine will be presented to the operators.

This

new generation of machines collects all of the technological updates and new

state of the art features for vacuum-pressure thermoforming with steel rule

cutting.

Visitors

to the WM stand A 47 in pavilion 22 will also be able to see a FT-700 punch and

die thermoforming machine with a lower tilting platen and automatic robotised stacking

system.

The

former with steel rule cutting FC 780 E Speedmaster Plus, which will be presented

on demonstration, features, among other facilities, a 4-column forming station,

with a closing force of daN 75,000, also suitable for incorporated cutting in

the same forming mould.

In

addition, the thermoforming machine has the second daN 60,000 press, of 4-columns,

for separate cutting and finally the stacking, counting and evacuation station.

The version with a two or three-axes robot manipulation system, which ensures

the widest range of stacking solutions for the diverse thermoformed products,

is already available.

The

machine can fit moulds up to a maximum size of 780 x 570 mm and is able to form

products with depths (negative and positive) of up to 130 mm.

As

mentioned previously, this line, named Speedmaster Plus, has also many new

features; a particular nod to the new processor for machine management and for

gathering together all of the production “recipes”. The new generation of B&R

PC use a digital interface that guarantees a high and precise speed of exchange

of the machine parameters.

The

software automatically manages the auto-setting of the cycle parameters on the

basis of the few elements requested to the operator.

Moreover,

the mechanics of the machine has been rationalised and new linear guides have

been introduced for positioning the cutting press and stacking stations. The

transducers have been replaced by absolute encoders and the pneumatic system

has been brought in line with the uses, as much as possible, by considerably

reducing the intervention times of the various functions, all the while reducing

consumption.

In keeping with principle of developing new

machines for the purpose of greater focus on energy saving, the WM systems

integrate a regenerative power supply that regenerates the kinetic energy

produced during motor decelerations by reinserting it into the network,

resulting in the consequent energy saving in the machine movement.

Another

new feature is the structure of the heating ovens and their positioning

according to the material pitch, which has also been provided with a great

possibility of division the heating zones in order to best adapt the system to

the type of material to process.

In

regards instead to the model FT 700 with a tilting platen relevant to the

demonstrations, there is a maximum mould size of 705x400 mm, a 150mm negative

depth of the thermoformed products and a closing force of 40,000 daN.

WM

Wrapping Machinery SA supplies also complete IN LINE plants, including the

extrusion and calendaring of the sheet.

Thermo Fisher Scientific Introduces New Versa RxV Checkweigher for Track/Trace

System Combines Checkweighing

with Coding, Verification

Thermo Fisher Scientific Inc.,

the world leader in serving science, today launched its new Thermo Scientific

Versa RxV checkweigher for track and trace applications in the global

marketplace. The company will demonstrate the new system at IPACK-IMA, February

28-March 3, 2012, at Fieramilano, Milan, Italy, hall 9, stand D28.

The Versa RxV addresses the needs of pharmaceutical and other products

which require track and trace capability. The all-in-one high-speed system (up

to 550 bottles/cartons per minute) combines code printing and verification (alpha-numeric

and machine readable) with checkweighing.

Because of increased counterfeiting and product recalls, there is a

heightened emphasis on tracking and tracing pharmaceutical products throughout

the distribution channel. The GS1 track and trace serialization standard calls

for individual drug package components (bottle, carton, shipping case, pallet,

etc.) to be marked with an identifying code. Codes must be unique, random and

unduplicated. Although the GS1 standard is currently voluntary, Food and Drug

Administration regulations making it mandatory could come as early as 2015.

“Pharmaceutical companies, as well as manufacturers of other products

such as food and cosmetics, are looking for cost-effective ways to integrate track

and trace capabilities into their production lines. By combining the key

elements of serialization—marking and verification—into the checkweigher, companies

save both cost and space,” said Kevin Zarnick, North America pharmaceutical

sales manager, Thermo Fisher Scientific.

Thermo Fisher’s customizable approach to building a Versa RxV enables

manufacturers to select which code printer and vision system brand is added to

the checkweigher frame. The modular build means that pharma companies can specify

the exact components they prefer.

A key differentiator of the Versa RxV from competitive all-in-one units

is its single operator interface. Instead of mounting separate user interfaces

for the checkweigher, code printer and machine vision system, Thermo Fisher has

incorporated control of all functions into one screen. This significantly improves ease-of-operation

and saves valuable line space.

Additionally, side belts with

horizontal and vertical adjustment ensure the correct position of the bottle or carton

during marking and verification. The checkweigher also features two reject

mechanisms—one for packages rejected by the vision system due to illegible or

incorrect codes and the other for over/under weights.

“The World Health Organization has estimated that up to 15 percent of

all medicinal products in the world are counterfeit. With more than $75 billion

in counterfeit drugs moving through the global supply chain, pharmaceutical

companies must take proactive measures to minimize the chance that illegally manufactured

drugs get into the hands of consumers. Adding track and trace systems to

production lines is one way to accomplish that objective,” Zarnick said.

The Versa RxV checkweigher for track and trace applications is backed by

the extensive worldwide Thermo Fisher service network. For more information

about Thermo Scientific checkweighers, please visit: www.thermoscientific.com/checkweighers.

About Thermo Fisher Scientific

Thermo

Fisher Scientific Inc. (NYSE: TMO) is the world leader in serving science. Our

mission is to enable our customers to make the world healthier, cleaner and

safer. With revenues of nearly $11 billion, we have approximately 37,000

employees and serve customers within pharmaceutical and biotech companies,

hospitals and clinical diagnostic labs, universities, research institutions and

government agencies, as well as in environmental and process control

industries. We create value for our key stakeholders through two premier

brands, Thermo Scientific and Fisher Scientific, which offer a unique

combination of continuous technology development and the most convenient

purchasing options. Our products and services help accelerate the pace of

scientific discovery, and solve analytical challenges ranging from complex

research to routine testing to field applications.

nice blog.Ishida India Pvt. Ltd PROVIDES MANUFACTURERS&SUPPLIERS OF High Speed automatic check weighing.

ΑπάντησηΔιαγραφή